Tools provided by AutomationML e.V.

General Related Tools:

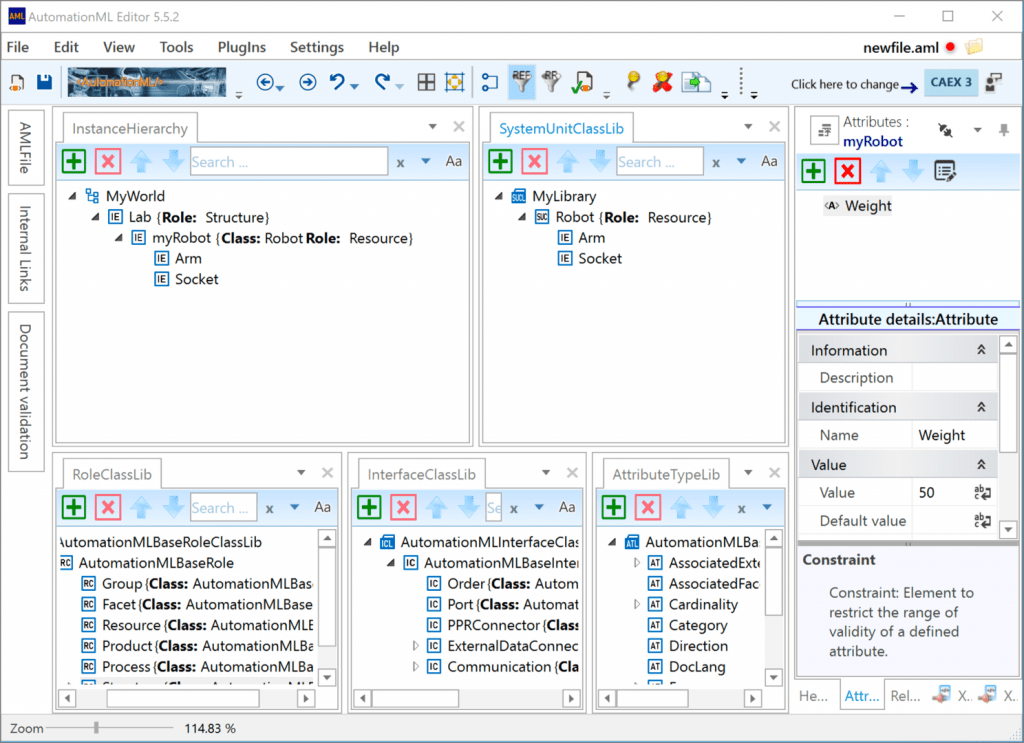

AutomationML Editor

This software has been developed by AutomationML association in order to visualise major AutomationML concepts and it provides functionality to visualise, create and edit AutomationML/CAEX files. AutomationML editor is suited for educational purposes and a perfect entry point for learning, experimenting and understanding AutomationML. Also have a look at Github.

AutomationML Engine

AutomationML engine is a free software for developers, developed by the AutomationML association. It exactly represents the CAEX data model in form of a C# class structure and contains classes and methods in order to manipulate CAEX objects (classes and instances). AutomationML Engine is also available on nuget.org. With this, developers can include the AutomationML Engine in their development environment and get informed when there are updates available. An API documentation you can find here: github.com.

Component Related Tools:

AutomationML Component Checker

AutomationML is used as modelling language to describe the content according to the definitions in the WP Component and to reference internal and external sub models for a single Automation Component. AMLX is used as package format to enable the shipment of such a model collection. Device suppliers need the AML Component Checker to ensure a minimum quality standard of their deliverables. The AML Component Checker shall in future become part of a larger AutomationML Component Suite, consisting also of an Editor functionality.

Tools Provided By Members

AML.hub

The AML.hub, developed at Neuron Automation and the CDL-Flex research laboratory at TU Wien, systematically integrates engineering tool networks that use the AutomationML standard and supports the automation of engineering processes. The AML.hub provides function for the management of an integrated plant model that reflects the contributions of all involved disciplines in a structured way. The framework helps minimizing the risk of changes that are not addressed correctly across disciplines and reduces costs.

CARF BIM Software

CAD and BIM software development for factory planning and technical building equipment

LuArtX was founded in 2018 and our team has many years of experience in MicroStation-based software development. We offer the best consulting for the CAD software CARF, your project environment and everything related to MicroStation. Here, too, we can draw on many years of expertise and respond quickly and in a solution-oriented manner.

Leading in the automotive industry

Our aim is to continuously expand the success story of the CARF CAD software for factory planning and technical building services, to adapt it to changing conditions and thus to offer the best solution. We are a well-coordinated team with which we operate close to the customer and react quickly to customer needs. We are proud to count the largest German automotive companies among our customer base.

AutomationML is used to export material flow data from CARF, for example.

RF::Suite

The RF::Suite offers a complete toolchain

- to perform virtual commissioning of robots or complex production lines,

- to reproduce the plant behavior in a Digital Twin, or

- to mirror the real plant directly into a Digital Shadow.

The maturity level of the plant can be increased in an early phase. Virtual models can be used for training purposes. Collected information form the basis for further analytics. These possibilities make the RF::Suite a holistic virtual tool over the entire life cycle of a production system.

Video: RF::Suite – A Short Overview

AutomationML is used to import topology, geometry, and kinematics information into RF::Suite products.

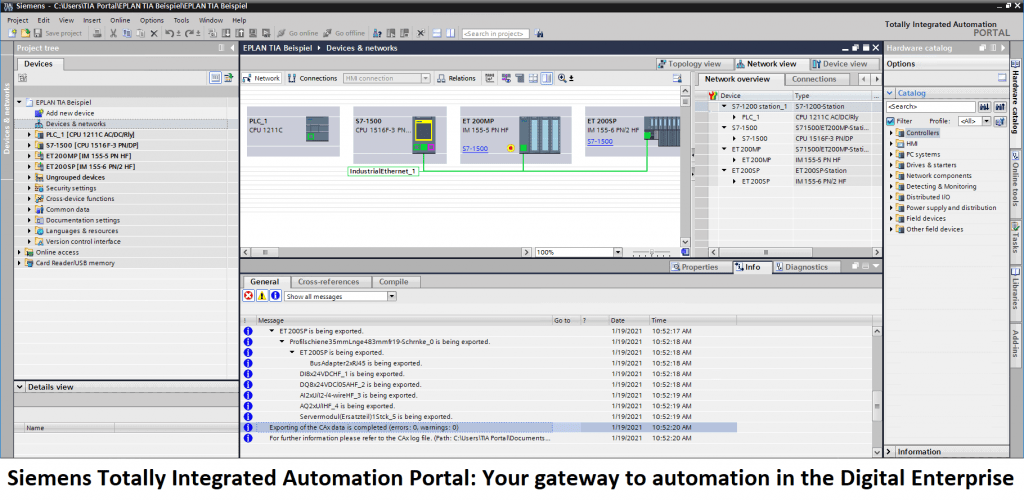

Siemens Totally Integrated Automation Portal

Your gateway to automation in the Digital Enterprise

Totally Integrated Automation Portal (TIA Portal) gives you unrestricted access to the complete range of digitalized automation services, from digital planning to integrated engineering and transparent operation.

Shorten your time to market with the aid of simulation tools, boost the productivity of your plant using additional diagnostic and energy management functions, and increase flexibility via connections to the management level.

taraVRBuilder

The layout planning tool taraVRBuilder, is a 3D design software in the material flow, conveying technology and plant planning field. With the help of this tool, facilities can be configured from modules of a standard library. Besides the construction of production lines and factory buildings of material handling, it is also possible to represent external models, such as machines, vehicles, workers, etc. Material flow can be described with different goods moving in different ways through the facilities. Animated 3D scenes are the focus of taraVRBuilder, which is providing a solution for the configuration of animated machines and facilities up to a medium complexity in a virtual 3D space. taraVRBuilder can export plain AML files, or AML together with COLLADA as the graphical content. It can also import COLLADA files as static geometry objects.

taraVRControl

taraVRControl is used to combine sensor data from real/virtual plants and installations with events of a 3D scene. In this way, it is possible to visualize a simulation of a virtual production system. Dynamic visualization components can also be set from an object library and their properties can be coupled with process variables. taraVRControl contains taraOPC2Control, an ActiveX component, in order to configure the 3D scene in an application which supports the integration of ActiveX components. This component enables the bidirectional communication between a 3D scene as an OPC client and an OPC server during runtime. Information, concerning the object characteristics, such as color, position, is read and changes in the process variables are visualized in the 3D scene. taraVRControl can import AML files to obtain topology and geometry information as well as COLLADA files as static geometry objects.