The Swedish Standardisation Organisation presents AutomationML as „Standard of the Month August“. The original press release can be found on the SEK website. Alternatively, you can find a free translation of the article below.

The background of the article by SEK Svensk Elstandard is the extension of the AutomationML standard by its 5th part – communication.

Many thanks to SEK Sevensk Elstand for this contribution and to Dr. Nicole Schmidt and Dr. Matthias Riedl for their explanations!

—

The AutomationML standard for industrial automation is now extended by a section on network communication.

With its meta model and the definition of data exchange formats, AutomationML makes data understandable and facilitates the transfer between software systems, suppliers and other participants along the value chain. This is according to Dr Nicole Schmidt, project manager in the Product Data Architecture department at Mercedes-Benz Tech Motion. She is also chairwoman of the working group of the international standards organisation IEC, which is working on the IEC 62714 standard for AutomationML.

Open and neutral

AutomationML is an open and neutral format for data exchange based on XML and specially adapted for industrial automation. The goal of AutomationML is to provide a vendor-independent format to support data exchange in an industrial plant, where different elements are described using different tools. AutomationML is object-oriented and enables the modelling of plant parts as data objects with different aspects and sub-objects. In August 2022, the new latest part of IEC 62714 was introduced as Swedish standard SS-EN IEC 62714-5.

Part 5 introduces the description of industrial communication networks and deals in particular with the topology of the network and the logical links between the communication partners, says Dr Matthias Riedl, who led the work on IEC 62714-5. Process data with real-time characteristics are often handled separately in communication solutions, he says, and the mapping of these communication relationships can be broken down to the variables in the controllers or in the field devices.

In addition, all parameterisation channels can be described so that diagnostic tools can precisely check whether the designed communication relationships have also been implemented correctly. All physical transmissions can be described based on this specification, e.g. whether they are wired or wireless.

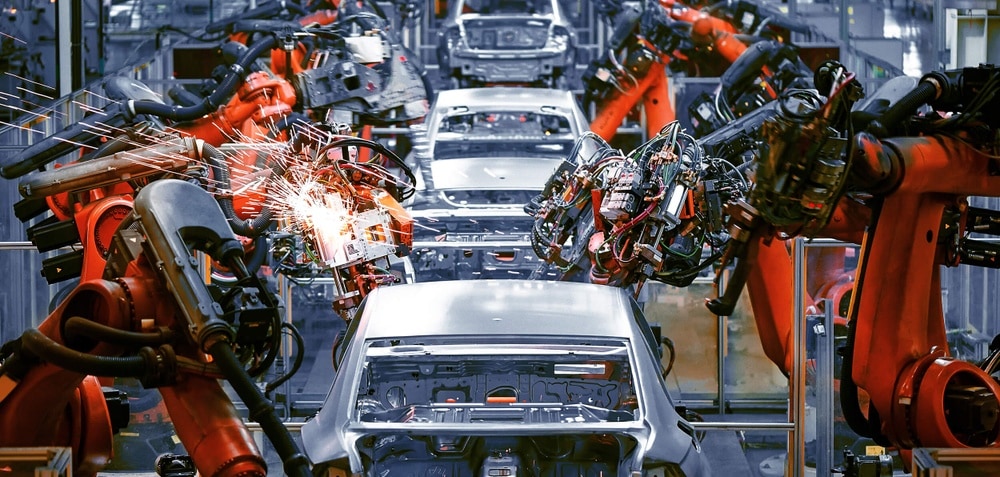

Automotive industry

Matthias Riedl is head of the ICT and Automation business unit at the German research institute IFAK in Magdeburg. When asked how AutomationML supports interoperability in the manufacturing industry, he answers: AutomationML is not limited to manufacturing technology, but can also be used in process technology. Thanks to the uniform exchange format, all tools involved in planning, commissioning or even diagnostics can process the information. Bus-specific roles can be derived from the roles defined in Part 5.

Back to Nicole Schmidt at Mercedes-Benz: Why AutomationML is important for the automotive industry?

AutomationML has always been important for the automotive industry and vice versa. You deal with complex projects where you combine the results of different suppliers to build mechatronic systems that produce the products the customer wants. Customers can order customised products. Therefore, state-of-the-art processes and software tools are used wherever possible, e.g. for virtual provisioning, in order to be as adaptable as possible and to reduce time-to-market. This puts a lot of pressure on data (data availability, data quality and easy and fast data transfer) to meet these challenges,“ she concludes.

Multiple standards

At the heart of AutomationML is the CAEX data format with a distributed document architecture. At the top level, information about the topology of the plant is stored, with cells, components, attributes, interfaces, etc. Information about geometry and movement is stored in the COLLADA format, which is linked to the associated objects in CAEX. Data on programme steps, signals and others are also stored separately and can be linked to CAEX according to IEC 62424 (SS-EN 62424).

Other parts of the standard for AutomationML are SS-EN IEC 62714-1, which specifies the general architecture and other basic concepts such as classes, relationships and hierarchies. The second part, SS-EN 62714-2, specifies role libraries and a third part, SS-EN 62714-3, deals with data formats for exchanging information about objects and shapes and about things that move, such as industrial robots. SS-EN IEC 62714-4 deals with modelling logic, sequences and behaviour.

IEC is the international organisation for standardisation in the fields of electricity, electronics, IT and related technologies. These standards originate from the technical committee IEC TC 65, Industrial process measurement, control and automation. Representatives from Swedish research and industry participate in the work there through the corresponding committee SEK TC 65 Industrial Process Control within SEK Svensk Elstandard, which has been a Swedish member of the IEC since 1907.

Other notable IEC TC 65 standards include IEC 61499 on functional blocks and the IEC 61508 and IEC 61511 series on safety critical systems („SIL standards“). Current projects include real-time networks (TSN) (IEC/IEEE 60802) and a unified reference model for smart manufacturing (IEC 63339).